Here is Belvie Chocolate’s story, in their own words…

Belvie Chocolate started with two people, who are ‘chocolate addicts’. In the beginning, we made our own chocolate just at home until we wanted to share our passion with the rest of the world, and that is when Belvie was born. Our chocolate is a combination of Belgian knowhow, in-depth chocolate knowledge, incredibly self-sourced beans form Vietnam and our love for Vietnam, farmers, nature and chocolate.

Belvie’s chocolate is handcrafted in small batches to maintain quality – for us, it’s all about the details without cutting corners. The beans are stone ground and conched for several days. We only use the finest trinitario cacao beans, which are purchased directly from different regions of Vietnam to enhance the local economy for our farmers. Other than making delicious chocolate of high quality, we also want to contribute to the preservation of cacao trees in Vietnam. Belvie do this by encouraging and supporting farmers by offering them a fair price for the beans they are sourcing.

Belvie source their beans from Lam Dong, Dong Nai, Tien Giang and Ben Tre.

How it all started.

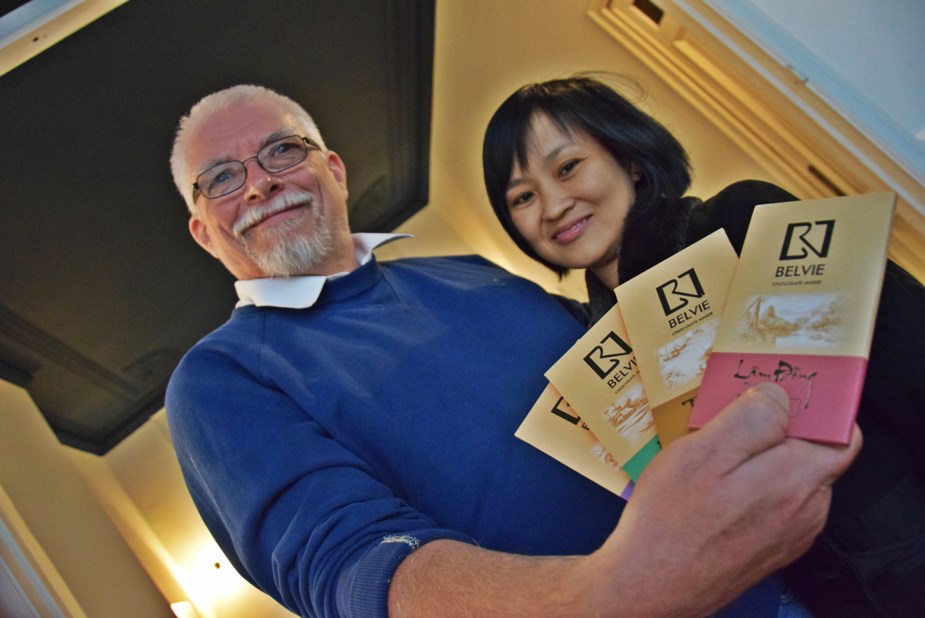

Belvie chocolate was cofounded end 2015 by Ms. Jannie Ha Tran (Vietnamese) and Marc Vanborren (Belgian). At the beginning, we started with two of us but now, 3 other people are involved in running the company but we hope soon to hire more people.

First, as we are chocolate addicts and living in the south of Vietnam where fine Trinitario trees are growing next to the door, we started making our own chocolate and slowly came the idea to share our passion with the rest of the world.

Secondly, understanding the cacao plantations in Vietnam are in a decline, and being from a Vietnamese farmers family we decided to do something on this by producing a high end product next to the plantations and by the same time helping the planters with a decent income as we buy the beans directly at an advantageous price.

The mission in the chocolate world

Our mission is to make fine tree to bar, bean to bar chocolate with as ingredient only cacao beans and cane sugar and some cacao butter from the same origin. We are not using Soya or any other lecithin. Regarding the process of making chocolate we want to make chocolate from each terroir in Vietnam. Only single terroir dark chocolate. We found the terroir is very important in the development of the flavour of the final chocolate. The same kind of trinitario beans growing in different terroirs are giving a complete different and sometimes diametric opposite flavour.

Our mission is also to develop the cacao plantations in South Vietnam in order to preserve the farmers to cut the cacao trees and give them a more than reasonable income.

Where we want to go in the chocolate world?

For the moment we are producing bars from 4 different Terroirs in Vietnam in different percentages of cacao. We have 70% 75%, 80%, 85%, 90% and 100% cacao. We make mostly in two sizes of bars 27gr and 80 gr We are also developing some bars mixed with species from the same region as the Cacao . So we developed a Coffee chocolate bar “ Good morning Vietnam “ with cacao beans and coffee beans from the central highland in the Lamdong province , our chili bar with 70% cacao, milk bar 55% cacao are also available in the collection.

Our next step is also to source in the other regions of Vietnam and develop our own plantations.

With all the honor, in three years, Belvie got some awards from Academy of Chocolate, London:

Gold 2017 for Lam Dong 70% cacao

Bronze 2017 for Tien Giang 70% cacao

Bronze 2017 for Hao Moc 80% cacao

Silver 2018 for Dong Nai 70% cacao

Silver 2019 for Ben Tre 70% cacao

In the coming months we will also develop our market . Actually we are available in the U.K, the U.S., Australia, France, Belgium, Denmark, Hongkong, Singapore and Vietnam .

Where we source our cocoa beans?

We source our beans directly at the farms. As the plantations in Vietnam are small ( between 1 and 2 ha ) we hunt for a few farmers with quality beans on the same terroir and we develop and follow up the plantation and the post harvest fermentation and drying together. We don’t work with cooperatives or middle man as we only want beans from a same terroir That way we also have a traceability about our raw material. As we are living close to the plantations we visit them often and can have an accurate phitosanitary control. We also develop with the farmers natural ways to fight against mold and insects by the use of ants and bats. We are also proud to offer the planters a much higher price than Faire Trade

Meaning of current packaging

On the mold as well as the wrapping, first we would like to show that it is Belvie product. Therefore, our logo must be printed on. Second, we want to show that the product is original from Vietnam. The name of the province, from which the beans come, has been written in a formal traditional Vietnamese way (Lam Dong, Dong Nai, Tien Giang, Ben Tre..). Moreover, the pictures can link to the geography of the region: Lam Dong is a highland area, Ben Tre, Tien Giang are Mekong Delta provinces… From the pictures, people can recognize the region. These are Vietnamese silk paintings.

The color of the bar is also something specific. Lam Dong is characteristic in red, Tien Giang is more caramel, honey in brown, Ben Tre is very natural with the green of trees and Dong Nai brings romantic feeling with the purple.

However, Good morning Vietnam is total in brown because it is the color of coffee and it is the very bright day (gold color of letters) after a peaceful night (dark back ground).

Our workshop

Our chocolaterie is located in Ho Chi Ming City (Saigon) between the two main Cacao plantations regions; the Mekong Delta with the famous Ben Tre and Tien Giang Province, and the Central Highland with the Lam Dong and Dong Nai provinces.

After we collect the beans at the farms, they are resorted by size and separate from any foreign materials and flat and bad beans in the factory and then bagged and stored in 50 kg jute bags, until the process of roasting. Our roaster is a modified 12kg batch coffee roaster.

Our cracker and winnower is an own developed and engineered model with an end result of around 99% husk free nibs. For the refining and conching of the nibs we are using 20 kg load melangeurs stone grinders.

The tempering is made with an continuous tempering machine UNICA built by FBM in Italy

For the moulds we took the option to make them locally in Saigon. So we made or design and Pierre a French friend, mould designer, made the metal master mould and produced the PC moulds”

Read an interview with Marc [external link]